This workbook will cover all of the

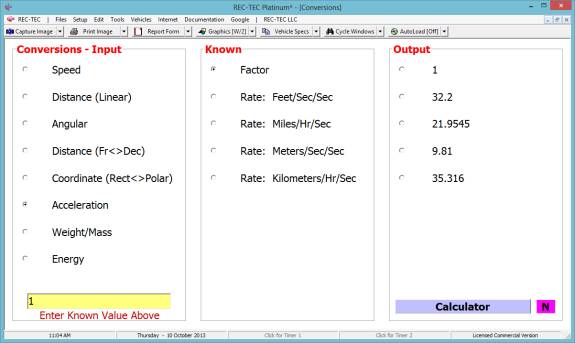

modules in the Platinum version of REC-TEC. Problems will be shown using the Imperial system of

measurement. REC-TEC can work in

any Imperial/Metric (or hybrid) system and can be switched between systems at

any time. It will assist in becoming

familiar with the various modules, and show how the program can solve very

different, difficult, and complex problems. The workbook uses a step-by-step

approach to REC-TEC accident reconstruction. It is not intended to teach the basics of accident

reconstruction, but to assist the accident reconstructionist in solving

problems using REC-TEC.

Fundamentals of Traffic Crash

Reconstruction,

Volume 2 of the Traffic Crash Reconstruction Series by John Daily, Nathan Shigemura, and

Jeremy Daily, published by IPTM, is highly recommended as a basic tool

for learning the science and art of accident reconstruction.

Figure 1

Figure 1 shows

the new Help (F1) & Manual/Tutorial (F5) selections on

the upper navigation bar (October 2015). Both are 'module sensitive' in REC-TEC Platinum.

REC-TEC

BASICS

REC-TEC takes a modular approach to accident reconstruction problem

solving, just as reconstructionists have always done. Each problem is broken down into solvable components:

·

Determine

the primary objective of the investigation.

·

Break the

overall problem down into solvable components.

·

Combine the

individual answers into a unified solution to the problem.

With these steps in mind, we will begin to

solve problems using REC-TEC.

It is suggested that you work the

problems on your computer as we go through them in the workbook in order to

receive the maximum benefit from this workbook.

Navigating

the Program

Before we begin to work problems, it may

be beneficial to take an in depth look at the main screen and take a tour of

the many features to get a better understanding of the functionality of the

program. In addition to the new module

sensitive selections on the upper navigation bar, the F1 F5 keys also

work from the Main screen. The F5

Key will call this document from the REC-TEC web site.

NEW *****

GLOBAL ENHANCED GRAPHICS (May 2014 Upgrade)

Figure

A

Figure A

displays the new "eGraphics" button on the Lower Navigation Bar. When the button shows eGraphics the new

graphics upgrades will replace the original graphics functions. Graphics and eGraphics are toggled using the

selection "Toggle Enhanced Graphics (Platinum)" on the Down Arrow

button to the right of the Graphics/eGraphics button as seen in Figure B.

Figure

B

eGraphics

consist of crosshairs that follow the cursor on selected graphics screens

throughout the program. Two or more

blocks will also appear with Time, Distance, Speed, or Lateral Distance

matching the crosshair position. The

crosshair position and data blocks can be "frozen" or

"unfrozen" using the [Ctrl] key. This allows the cursor to be moved for other purposes such as

clicking on the Report button to place the image in the report, or drawing on

the image using the right mouse button as in original Graphics.

Modules with the

enhanced graphics include:

·

Collision Avoidance Following Maneuvers

·

Collision Avoidance Turning Maneuvers

·

Time Distance Acceleration

·

Time Distance Deceleration

·

Time Distance Multiple Vehicles

·

Time Distance Omni

·

Time Distance (EDM)

eGraphics is a

Platinum Option only upgrade that also includes a unique new feature in the

Time Distance (EDM) module. When the

crosshairs are on the TD-EDM graphics, clicking on the left mouse button will

immediately capture the point on both curves where the vertical crosshair is

located and will place the corresponding Time, Distance, and Speed in the

center data blocks below the graphics.

As before, the

Data blocks below the Graphics screen can still be used to find and position a

set of crosshairs on the Graphics corresponding to a Time, Distance or

Speed. The new eGraphics permits using

the vertical crosshair to select a position on the either curve and get the

corresponding Time, Distance, and Speed information.

CONFIGURATION

(Table of Contents)

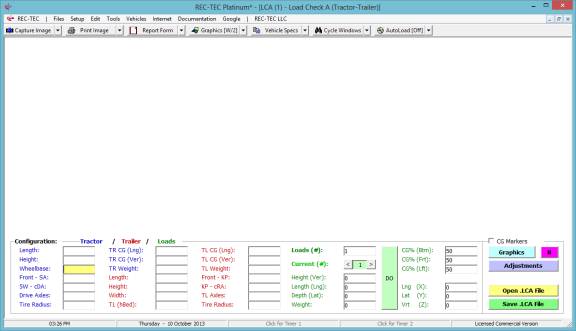

Figure

2

On the upper navigation bar of the main

screen, select Setup > REC-TEC (Figure 2) to call up the Configuration

screen (Figure 3). All problems will

assume the following configuration unless otherwise specified:

Figure

3

The preferences selected using the Configuration

screen (Figure 3) will be set every time the program is started. This screen may be called at any time to

change the preferences set at program start. Temporary changes can be made in

the various modules or by using the Graphics Icon (or drop-down) on the

main screen.

The configuration screen will set the

basic input/output displays throughout the program as well as which additional

programs REC-TEC will call

(word processors, drawing packages, etc.).

The F1 help files may be translated into many languages. Use the F7 key to pull up the HTML file from

the website and right clicking on the English version in order to use one of

the many Translation Accelerators now available.

Many display options can be set here as

the default, but can be changed temporarily from the Graphics icon on

the lower navigation bar.

Modules

REC-TEC consists of various modules that, by treating your

computer as a computer instead of a calculator, compute the answers for the

maneuver, not just a single formula.

Most modules offer iteration and graphics. Many offer animation and finite difference analysis. These tools

will assist the professional in analyzing the problem and help provide

confidence in the solutions. Many of

the modules will integrate with other modules, providing additional analysis

and support.

Upper Navigation Bar

(Table of Contents)

Opening a module At the REC-TEC pull down menu (upper navigation bar

left side), select Time - Distance then Acceleration - Deceleration

(Rate/Factor) from the submenu (Figure 4).

Figure

4

Note: Modules followed by an

asterisk are capable of generating an animation text file. These files can be imported into third-party

animation software capable of creating high-resolution animation using the X,

Y, and Z positions for each time key frame computed by REC-TEC. A list of these modules and what is required

is in the Manual > Overview Help file.

Click

on Acceleration - Deceleration (Rate/Factor) and the Time - Distance

Acceleration - Deceleration screen appears (Figure 5).

Figure 5

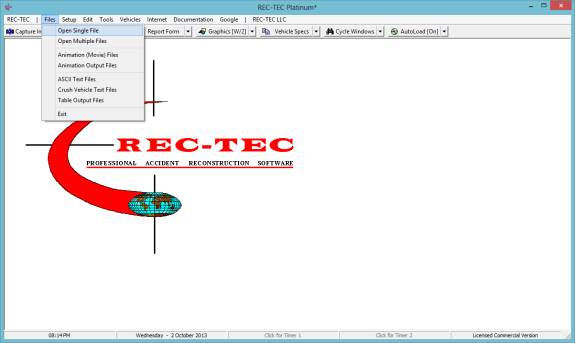

As an alternative, a file (or multiple

files) can be selected from the upper navigation bar Files > Open Single

File (Figure 6) or Files > Open Multiple Files.

Figure

6

This will call up a box showing all of

the files in the Folder selected.

Figure 7

Clicking on Open will call up the

Module and automatically open the file in the appropriate module (Figure 8).

Figure 8

If Open Multiple Files is selected, the

user may open multiple files in one or more modules. To end this process, click on the Cancel button in the file

display box.

Notice in Figure 8, on the lower

navigation bar on the right hand side the icon labeled AutoLoad. In Figure 8, AutoLoad is turned off (AutoLoad[Off]). When a module is exited, or the program is

exited, all modules save their current data to a file named Lastfile

with the appropriate extension for the particular module.

Caution if multiple copies of the same module are opened with

different files, be sure to save the data as named files as the last module

to close will overwrite the other Lastfile in identical modules.

Files Opening and Saving Files

Almost every module allows saving the

data to a file that can be re-opened later, redisplaying the original

computations. Each of these text files

carries an extension (.???) unique to a particular module. When a module is closed, the data (or lack

of data) in that module is automatically saved as Lastfile.(ext). If AutoLoad is set to [On], the file for the

module will open using this Lastfile.(ext) unless the module is opened by

selecting a particular named file.

Once a module is open, a file can be

opened at any time using the Open .EXT File button.

The Save .EXT File button will

save the data with a user selected name.

Other Files options are available which

call up text files produced by various modules for third party animations. Many popular movie (animation) formats can

also be called up using the Files menu.

Setup

The submenu > REC-TEC calls up the Configuration screen, which

can be viewed or modified.

The submenu > Reset

Defaults calls up the Configuration screen with

the default settings, which can be viewed or modified.

The (Figure 9) submenu > View permits the

user to independently view or hide the lower

(Icon) navigation bar and the Status bar at the bottom of the screen.

Figure 9

Figure 10 (Removed in 2015) - Functions Duplicated

on Lower Navigation Bar

Edit

(Figure 10) - (Functions duplicated on Lower Navigation Bar)

Figure 11

Tools (Figure 11)

·

Submenu >

Calculator: Windows Calculator

(Switches between Normal and Scientific).

·

Submenu >

Drawing Program: Set on

Configuration screen.

·

Submenu >

Word Processor: Set on

Configuration screen.

·

Submenu >

Contract (Recon-Attorney): Sample

contract.

·

Submenu >

Defaults & Rules of Thumb:

Collection of values.

·

Submenu >

Formulae: Formulae used in

program (two formats).

·

Submenu >

Glossary (rsmck.com): Useful

AR glossary.

·

Submenu >

Hazmat Data: Hazmat information.

·

Submenu >

Railroad Information (rec-tec.com): Useful Railroad information.

·

Submenu >

Request for Production (RR): Sample

document (Railroad).

Figure 12

Vehicles (Figure 12)

·

Federal

Motor Vehicle Safety Standards (571)

·

Federal

Motor Carrier Safety Regulations (590)

·

NHTSA

Crash Database (Internet)

·

NHTSA

Recall Database (Internet)

Figure 13

Internet

- Useful

AR Internet Links (Figure 14)

- REC-TEC

Internet Links

- REC-TEC

Web Browser

- REC-TEC Version Check (Removed 2015 - Click on

License Name)

- REC-TEC

Upgrade (Download)

- Online

Articles

- Email

REC-TEC

Figure 14

Documentation (Figure 15)

- REC-TEC

- Email Information for License

- All

F1 Key (Help).PDF Files

- [F1]

key Program Overview or Help

- [F2]

key Finite Difference Analysis Overview

- [F3]

key Animation Overview

- [F4]

key Module Overview

- [F5]

key Inside REC-TEC (www.rec-tec.com)

- [F6]

key Same as [F1] key

- [F7]

key Same as [F1] key (www.rec-tec.com)

- [F8]

key Inside REC-TEC (PDF)

- [F9]

key REC-TEC Startup Guide (PDF)

- [F10]

key REC-TEC Version Check (www.rec-tec.com)

- About

Coordinate Systems (Diagram of

Coordinate Systems)

- Printing

Reports and Graphics (Figure 16)

Figure 15

Figure 16

Google

·

Calls Google

for Answers to many AR/Other questions

Name

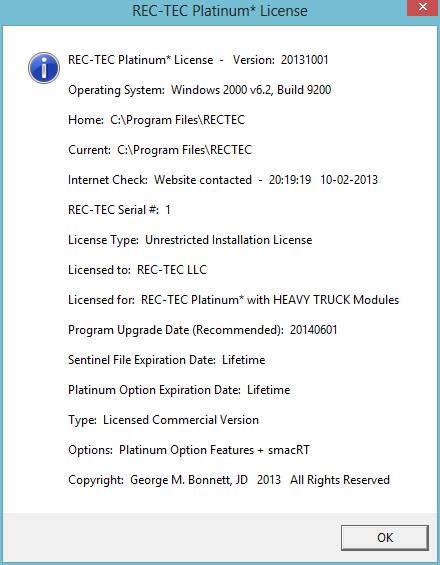

·

REC-TEC

License (Figure 17)

Figure 17

Radio Button Functions

To the right of certain (Primary Output)

Speeds in selected modules there is a Radio Button that will transfer

the value of the Speed to the Windows Clipboard for transfer into

other modules within REC-TEC or anywhere else the user may select using

the Paste option after Right Clicking on the Mouse. This option

appears on the following modules:

Time Distance Multiple Surfaces (Initial

Speed)

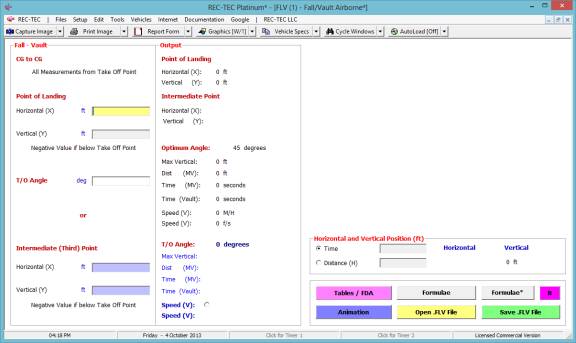

Fall-Vault Airborne

Vault-Slide Integration

Yaw-Critical Speed of a Curve

Kinetic Energy

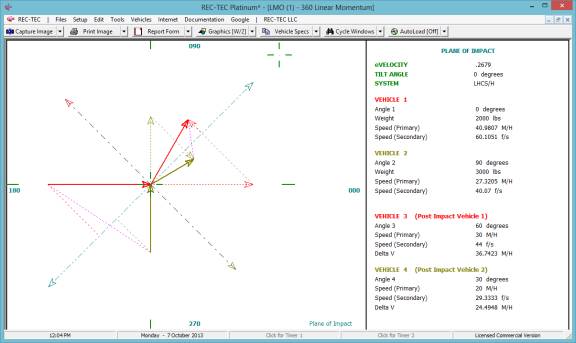

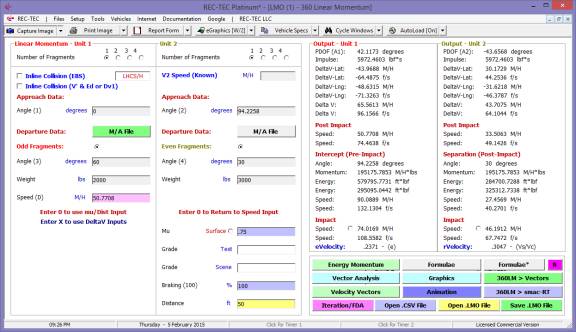

360 Linear Momentum (Impact Speeds)

At every entry point in the program calling

for an Acceleration/Deceleration Factor, there is a small round Radio Button.

Clicking the Radio Button will cause the Acceleration/Deceleration Factor

module to appear. Computations can be made for timed or measured vehicle tests

or for Drag Sled Pull weight divided by Sled weight. The user may

then transfer the result of the computation and Exit the module or Exit the

module without transferring a value.

Lower

Navigation Bar (Icons and dropdown menus) See Figure 1

(Table of Contents)

·

Capture

Image Captures REC-TEC

Image on Clipboard

o

Capture

Entire Screen

o

Capture

REC-TEC

o

Capture

REC-TEC (Active Form)

o

Capture

Active Window (time delayed capture)

o

Display

Captured Image (Displayed on REC-TEC Form)

o

Clear

Current Image

·

Print

Image Prints REC-TEC

image to default printer

·

Report

Form Sets link to

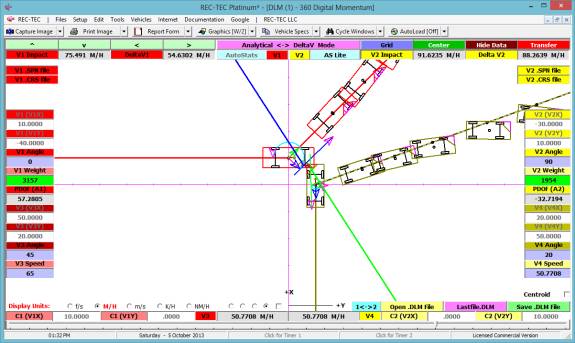

Word/WordPad/Adobe printer driver

o

Display

Help Printing

o

Initiate

Document Link with Word (Integrated)

o

Initiate

Document Link with WordPad (Integrated)

o

Activate

PDF (Adobe) Document Spooler

o

Copy

Image to Report

o

Close

Document (Spooler to PDF Document)

·

Graphics

Toggles Graphics

background color

o

Toggles

Background Color (Blue/White)

o

Graphics

Line Width = 1 (Session only)

o

Graphics

Line Width = 2 (Session only)

o

Graphics

Line Width = 3 (Session only)

o

Graphics

Line Width = 4 (Session only)

o

Graphics

Line Width = 5 (Session only)

·

Vehicle

Specs Calls AutoStats

Lite from 4N6XPRT Systems

o

List of

4N6XPRT Vehicle Specs programs installed on computer (if any)

o

Canadian

Vehicle Specs (Windows Version)

o

Sisters

and Clones

o

Motorcycle

Specs (Internet)

·

Cycle

Windows Cycles

(multiple) modules to foreground

o

Cascade

o

Tile

Horizontally

o

Tile

Vertically

o

Arrange

(Icons)

o

Minimize

All

o

Restore

All

o

Close All

·

AutoLoad

Toggles AutoLoad[On/Off]

o

Save

Change

o

AutoLoad

ON

o

AutoLoad

Off

Module

1: Time - Distance Acceleration-Deceleration

(Rate/Factor)

(Table of Contents)

Overview: This module

computes Acceleration/Deceleration factors and rates based on supplied

information.

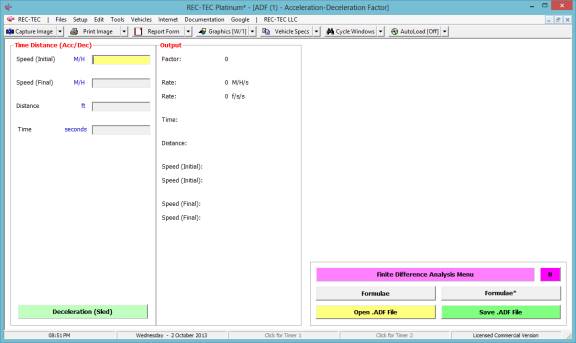

At the REC-TEC pull down menu, select Time - Distance >

Acceleration-Deceleration (Rate/Factor) and the Time - Distance -

Acceleration-Deceleration (Rate/Factor) screen appears (Figure 18).

Figure 18

Input

Data

This module has four data inputs (No required

inputs)

- Initial

Speed

- Final

Speed

- Distance

- Time

Two or three inputs are required to

generate a solution.

·

If Distance and Time inputs are used, the module

will compute a solution. If a Speed input is added, the module

solves for the unknown speed input.

·

If a Distance and a Speed input greater than zero is

used, the module will compute a solution.

If Time or a second Speed input is added, the module

will solve for the remaining unknown.

·

If two Speed inputs are

used, either Time, or Distance is required. The module will solve for the remaining

unknown.

Example 1: A vehicle

accelerates at a uniform rate traveling 100 feet in four seconds.

1. What is the

acceleration factor?

2. What is the

acceleration rate?

3. What is the

final speed? Is there a way to

determine the final speed with the information given?

Figure 19

Example 2: A vehicle

accelerates from 20 M/H at a uniform rate traveling 100 feet in three seconds.

4. What is the

acceleration factor?

5. What is the

acceleration rate?

6. What is the

final speed?

Figure 20

Example 3: A vehicle

decelerates to a stop at a uniform rate traveling 100 feet in three seconds.

7. What is the

deceleration factor?

8. What is the

deceleration rate?

9. What is the

initial speed?

Figure 21

Figure 22

Figure 22 shows the Finite Difference

Analysis menu for the Acceleration/Deceleration factor.

Figure 23

Figure 23 shows the results of the Finite

Difference Analysis. This analysis is

for the Acceleration (or Deceleration) factor only. It does not include the speeds unless they are part of the

computation.

Iteration and Finite Difference Analysis

Iteration (table generation) is available in all versions of

REC-TEC and is almost

self-explanatory. It will be demonstrated

in the Time - Distance Single Surface Deceleration, 360 Linear Momentum, S-CAM

Air Brake and other modules that may represent unique variations on the basic

iteration model.

Finite Difference Analysis (FDA), which computes an Uncertainty Level based on a specific range of

the variables within a formula, is restricted to the Platinum Version of the

program. A general explanation of the

principles of FDA is called up by using the F2 key from any module offering

FDA. FDA will be demonstrated in the 360

Linear Momentum, S-CAM Air Brake and other modules that may represent unique

variations on the basic FDA model.

SAE paper 2003-01-0489 Evaluating Uncertainty in Accident

Reconstruction with Finite Differences by Wade Bartlett

and Al Fonda compares Finite Difference Analysis with the Monte Carlo type of

computations done by various high-powered statistics programs on the market.

For the same given ranges of the variables involved, the answers are identical.

Example 4: A 45-pound

drag sled has a pull weight of 33 pounds.

Select Deceleration (Sled) this selection is made from the

screen shown in Figure 21.

10. What is the

deceleration factor?

11. What is the

deceleration rate?

Figure 24

Figure (24B)

Figure (24B)

shows the screen, as it would appear if it were called up using the new Radio

Button feature already described above.

The factor can be transferred automatically to the input on the

calling module or this page can be exited without transferring.

Module

2: Time - Distance Acceleration

Single Surface

Overview: This module computes detailed information on the Speed,

Distance and Time of a single acceleration event.

At the REC-TEC pull down menu, select Time - Distance >

Acceleration - Single Surface and the Time - Distance - Acceleration screen appears (Figure 25).

Figure 25

Required Input Data:

Acceleration Factor (fa):

The percentage of gravity used to accelerate the vehicle. The acceleration factor is entered into the

program as a decimal value representing a percentage of gravity available to

accelerate the vehicle.

Example 1:

The vehicle has an average acceleration factor of .25 g during the

maneuver.

1.

How fast was

the vehicle traveling at the end of the acceleration if it started from a full

stop and accelerated for 200 feet?

2.

How long did

the acceleration take?

Solution: Enter into the module the required data:

- Acceleration Factor (.25)

- Initial Speed (0)

- Distance (200)

With this information, the final speed is computed at 38.6898 M/H

(question # 1) and a time of 7.049 seconds to accelerate from a full stop

(question # 2) as illustrated in Figure 26.

Figure 26

Example 2:

3.

How fast was

the vehicle traveling at the end of the acceleration if it started from 20 M/H and

accelerated for 200 feet?

4.

How long did

the acceleration take?

Figure

27

With this information, the final speed is computed at 43.5534 M/H

(question # 3) and a time of 4.2913 seconds to accelerate from 20 M/H (question

# 4) as illustrated in Figure 27.

Example 3:

5.

How fast was

the vehicle traveling at the start of the acceleration if it accelerated for

200 feet to a final speed of 60?

6.

How long did

the acceleration for the 200 ft. take?

7.

How long did

the acceleration take if it was from a full stop to 60 M//H?

8.

What was the distance

covered in Question 7?

Figure 28

With this information, the initial speed is computed at 45.8595

M/H (question # 5) and a time of 2.5763 seconds to accelerate for 200 ft. to a

final speed of 60 M/H (question # 6) as illustrated in Figure 28.

The time from full stop to 60 M/H is computed to be 10.9316

seconds (question # 7) and the total distance is 480.9937 feet (question # 8)

as illustrated in Figure 28.

Iteration and Finite Difference Analysis

Iteration (table generation) is available in all versions of

REC-TEC and is almost

self-explanatory in nature, it will be demonstrated in the Time - Distance

Single Surface Deceleration, 360 Linear Momentum and the S-CAM Air Brake

modules, as they each represent unique variations on the basic iteration model.

Finite Difference Analysis (FDA), which computes an Uncertainty Level based on a specific range of

the variables within a formula, is restricted to the Platinum Version of the

program. A general explanation of the

principles of FDA is called up by using the F2 key from any module offering

FDA. FDA will be demonstrated in the

360 Linear Momentum and the S-CAM Air Brake modules, as they each represent

unique variations on the basic model demonstrated in the Time - Distance Single

Surface Deceleration, module.

Module

3: Time - Distance Deceleration

Single Surface

(Table

of Contents) (Table of

Contents)

Overview: This module computes detailed information on the Speed,

Distance and Time of a single deceleration event. If lateral information is

input, the module also computes detailed swerve and swerve-and-return data.

At the REC-TEC pull down menu, select Time - Distance >

Deceleration - Single Surface and the Time - Distance - Deceleration screen appears (Figure 29).

Figure

29

Required

Input Data

Coefficient

of Friction Mu: The coefficient of friction is defined as

the percentage of gravity developed at the tire-road interface for acceleration

(deceleration). The coefficient of

friction is entered into the program as a decimal value representing a

percentage of gravity available to decelerate the vehicle.

Grade Grade is the rise or fall of the

roadway. It is either a negative

downhill grade or a positive uphill grade and is dependant upon your direction

of travel. You may often hear it

referred to as the slope of the road.

Grade is determined by the ratio of the rise of the roadway divided by

the run or length of the measurement. It is the tangent of the angle.

The Grade of the roadway is entered into

the program using a positive uphill or negative downhill decimal value. If no entry is made, the module treats the

grade as zero.

Braking

Percentage the braking

efficiency of the vehicle is a determination of how much of the entire weight

of the vehicle is being overcome by the brake force generated at the

wheels. As the vertical weight at each

brake point increases, a limit is reached when the components of the brake

assembly will no longer generate enough force to overcome the rotational torque

of the wheel. This limit is dependant

upon the vertical weight component on each wheel and the overall mechanical

condition of the brake components.

Braking efficiency is entered in the

program as a whole number percent value as opposed to a decimal value. Full braking on all wheels is entered as 100

(100%).

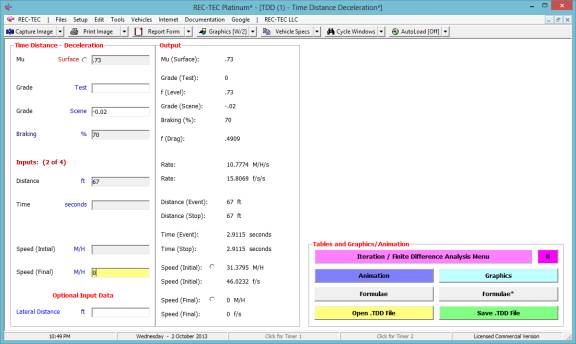

Example 1: A

vehicle skids 47 feet before striking a pedestrian crossing the roadway. It continued for an additional 20 feet

before coming to a complete stop. An

accelerometer was used to conduct skid tests and it was determined that the

coefficient of friction of the roadway was 0.73. The grade at the accident site was a negative 2% and the crash

vehicle had a overall braking efficiency of 70%.

- How

fast was the vehicle traveling at impact with the pedestrian?

- How

fast was the vehicle traveling when the driver first applied the brakes?

- How

long did it take the vehicle to skid to a stop?

- How

long did it take the vehicle to skid to impact with the pedestrian?

- If

the vehicle would have had 100% braking, would the collision with

pedestrian occurred?

Solving

the problem

Step

1: Determine from the problem what data

is available for input into the module

- Distance of skid to impact: 47 feet

- Distance of skid after impact: 20 feet

- Total distance of skid: 67 feet

- Ending speed/velocity: 0 mph

- Coefficient of Friction: 0.73

- Grade:

-0.02

- Braking efficiency: 70 %

- Optimum braking efficiency 100%

Step

2: Enter into the module the required

data:

- Coefficient of Friction

- Grade at crash site

- Braking efficiency

Figure

30

Solution: This module requires two of the following four variables to reach

a solution.

- The

beginning speed/velocity,

- The

ending speed/velocity,

- The

distance of skid,

- The time

of the skid.

From the information given, we have two

known values that can be used to determine a solution and answer the general

questions that may be raised during the normal course of our

reconstruction. We know that the vehicle skids to a stop and therefore have an ending

speed/velocity of 0 mph. We also know that the vehicle skids 47 feet

pre-impact, 20 feet post-impact for a total skid distance of 67 feet. Using these two known values we can answer

Question 2 and Question 3 of our problem.

Step

3: Enter 67 feet as the distance of

skid to a stop and 0 miles per hour as the final speed of the vehicle.

With this information, the initial speed is computed at 31.3795

M/H (question # 2) and a time of 2.9115 seconds to skid to a full stop

(question # 3) as illustrated in Figure 31.

Figure

31

Question #2 concerning the initial speed of the vehicle (31.3795

M/H) and question #3 about the time to decelerate to a stop (2.9115 seconds),

have now been answered. The program has

computed the speed at the start of the deceleration as 31.3795 M/H and while

the reconstructionist would never use a four decimal point answer for the

initial speed in testimony, this is our computed initial speed for further

computations.

Enter the initial speed/velocity of 31.3795

M/H and the distance to the pedestrian of 47 ft as known values.

Figure

32

The program has now computed the answers

to question # 1 (17.1444 M/H) and question # 4 (1.3208 seconds). The only question left is #5.

By entering 100 for the percent of

braking, we find that a distance of 46.3337 feet is required to come to a full

stop and that at 47 feet the vehicle would be traveling at 3.7629 M/H. The

collision with the pedestrian would not have occurred.

Figure

33

Figure 34

The Formulae* button will bring up

a screen showing the formulae required to compute the two missing variables

(Figure 34).

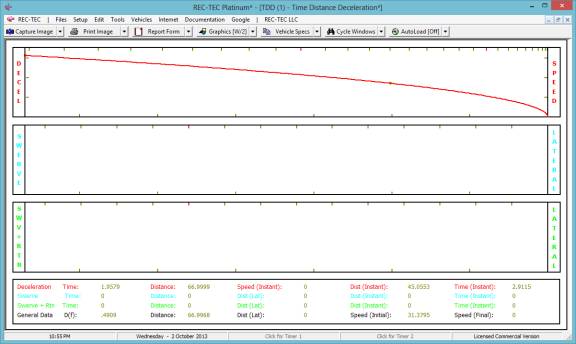

The Graphics button will show the Speed

versus Time and Speed versus Distance graphs.

In Figure 35, the curves are shown for 70%

braking.

Figure

35

The Animation button will display the

deceleration curve for the Time or Distance entered in the blocks in Figure

36. Entering a number greater than 1

will display the animation in slow motion.

Figure

36

Notice that in Figure 37 the 47 foot mark is shown as a

small circle on the curve.

Figure

37

This module has an optional input

Lateral Distance. This distance could

be the width of a lane or the distance the vehicle must move laterally in order

to miss the object. This module

computes the lateral movement based on the full friction value of the

coefficient of friction. The following

figures will show a Lateral Distance of 12 feet. The additional data the module

is able to compute is displayed in Figure 38 and described more fully in the

Help file available by using the F1 key while in this module.

Figure

38

Figure 39

The Formulae* screen now displays

the basic formulae and computations for the distances required for the Swerve

and Swerve & Recover Distance computations as shown in Figure 39.

Swerve-No Return shows what would happen if the vehicle

were placed in a maximum rate change of direction using the coefficient of

friction (modified for grade). This is

the same as using a .71 G turn using the numbers in this example. This would allow the vehicle's center of

mass (or any given point of reference) to pass 12 feet laterally from the

initial path of travel. This would NOT

have the vehicle headed on a parallel path; it would be headed in a different

direction (like off the road and into the boonies?). If the vehicle were brought back to a parallel path, the distance

and time would be doubled as would the total lateral distance.

Swerve and Return shows what would happen if the vehicle

were placed in a maximum rate change of direction using the coefficient of

friction (modified for grade) with an immediate change to a maximum rate change

of direction in the opposite direction, at the optimum point to accomplish the

maneuver. This allows the vehicle's center of mass (or any given point of

reference) to pass 12 feet laterally from the initial path of travel. This has the vehicle headed in a parallel

path. This is a lane change maneuver.

Critical Turnaway is a Speed at which the Distance

Slide to Stop and the Distance required for the Swerve (or Swerve

and Return) maneuver are identical. Critical Turnaway is a Speed at

which two distances are identical. It is similar to a point of no return.

Critical

Turnaway Distance Distance

for both Slide to Stop and Distance required for the maneuver

Critical

Turnaway Time Time

required to stop from the Initial Speed

Critical

Turnaway Speed The Speed

at which the Distance Slide to Stop and the Distance required for the Swerve

(or Swerve and Return) maneuver are identical

The enhanced Animation is shown in Figure

38. The animation (real time or slow

motion) can be paused and continued using the Spacebar. Moving the mouse over the graphics or

animation while depressing the left mouse button enables drawing on the

screen. The right mouse button will

cause a re-draw.

Figure 40

Iteration and Finite Difference Analysis

The Iteration/Finite Difference

Analysis Menu button calls up a menu (Figure 41) that will generate

iteration tables and initiate a Finite Difference analysis based on the values

entered as the Minimum and Maximum values of the variables. See additional information on FDA using the

F2 key.

Figure 41

In Figure 42, the appropriate variables

are ranged and the desired interval for the iteration has been entered.

Figure 42

Figure 43 shows the table generated for

the drag factor (adjusted for braking) solving for the Initial Speed keeping

the Distance and Final Speed constant as selected in Figure 42.

Figure 43

Figure 44

Figure 44 shows a finite difference

analysis for the final speed (speed at contact with the pedestrian) based on

ranging the Drag Factor, Distance and Initial Speed generating an uncertainty

value of 6.064 M/H.

Module

4: Time - Distance Multiple Vehicle

Overview: This module computes comparative data

for two vehicles in two individual acceleration, deceleration or constant

velocity events and offers animation of the maneuver.

At the REC-TEC pull down menu, select Time - Distance > Multiple

Vehicles and the Time

Distance Multiple Vehicles

screen appears (Figure 45).

Figure 45

Required

Inputs

The required

input data depends on the user-selected maneuver for each vehicle or

object. Single-Surface Acceleration and

Single-Surface Deceleration modules can be referenced for information on the

required input data for these maneuvers.

Constant Velocity will require the Initial Speed and the

Final Speed as inputs, and they must be identical.

Example

1:

Vehicle 1 decelerates from 60 miles per hour to a final speed of 15

miles per hour (striking vehicle 2).

The Mu value is 0.6 and the grade is zero. The braking is 100%.

Vehicle 2 accelerates from 7.5 miles per hour to a final speed of 30

miles per hour (striking vehicle 1).

The acceleration factor is 0.2.

This module allows some unique options

such as CLOSURE, which can help investigate the sight triangle between

the two units involved. Either vehicle

can be studied for any time or distance before the event in question, be it a collision,

stop, or any point under consideration

For this problem, two vehicles will be

taken into collision. Tables can be

generated to study what happened before impact. With the ability to look at units in any combination of

acceleration, deceleration, or constant velocity, any situation can be

analyzed.

This section can be used to analyze

vehicles, or vehicles and pedestrians in collision. This section can also be used to study the effects of different

values for the same vehicle (side by side).

Figure 46

1.

How fast was

Vehicle #2 going when vehicle #1 was 1.5 seconds from impact?

2.

How far from

impact was Vehicle #1 when Vehicle #2 was 5 seconds from impact?

Figure 47

If the vehicles end together at Time = 0,

and a .5 second time interval is used, a speed table can be created that will

answer the question.

The answer to

question #1 is 23.4136 M/H (Figure 48)

Figure 48

The answer to

question #2 is 327.267 feet. (Figure 48)

3.

When Vehicle

#2 was 25 feet from impact, what was the speed of vehicle #1?

Figure 49

The answer to

question #1 is 22.8246 M/H (Figure 49)

The Closure button computes

data on the triangle using the two vehicles and impact.

Figure 50

The Execute button displays

(Figure 51) the triangular relationship defined by the angles entered in the

blocks on Figure 50.

Figure 51

The Graphics button (Figure 46) brings up a menu (Figure 52)

controlling the graphics curves (Time or Distance and the values involved)

displayed on the screen (Figure 53).

Figure 52

Figure 53 shows the time curves for the greater

time of the acceleration.

Figure 53 (Time)

Selecting Distance on the menu shown on

Figure 54 and increasing the total distance from 187.8881 feet to 250 feet

shows the graphics on Figure 55.

Figure 54

Figure 55 shows the distance curves for

the increased distance of 250 feet.

Figure 55

The Animation button (Figure

46) brings up a menu (Figure 56) controlling the way animation is displayed on

the screen.

Figure 56

After engaging the options of choice on

this menu (Figure 56), the Execute button will initiate the animation (Figure

57).

Figure

57

Example

2:

Vehicle 1 decelerates from 60 miles per hour to a final speed of zero.

The drag factor is 0.72. Vehicle 2

decelerates from 60 miles per hour to a final speed of zero. The drag factor is

.61. Vehicle 2 is "Trailing"

100 ft. behind Vehicle 1. Vehicle 2 has

a 1.5 second perception reaction time (PRT) when Vehicle 1 brakes. There is no grade and the braking is 100%

for both vehicles.

Figure

58

Once the problem is setup up, select

Animation. Select "From

Start" and use the parallel format.

Answer the remaining questions using the information listed above. Select compute for TIME.

Figure 59

Figure 60

Do the vehicles hit? At what speed?

Vehicle 1______________________

Vehicle 2______________________

Example

2A: How would

the answer change if the PRT was 2 seconds and the trailing distance was 75

feet?

Do the vehicles hit? At what speed?

Vehicle 1______________________

Vehicle 2______________________

Example

2B: How would

the answer change if the PRT was 1 second and the trailing distance was 150

feet?

Do the vehicles hit? At what speed?

Vehicle 1______________________

Vehicle 2______________________

Module

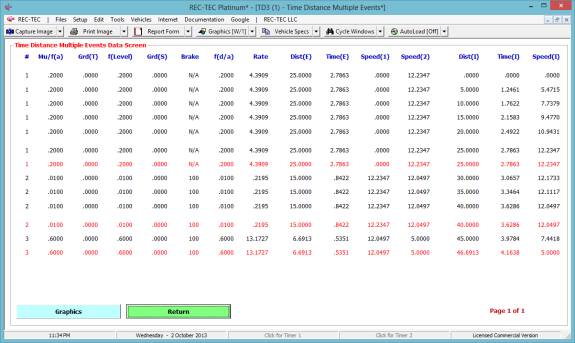

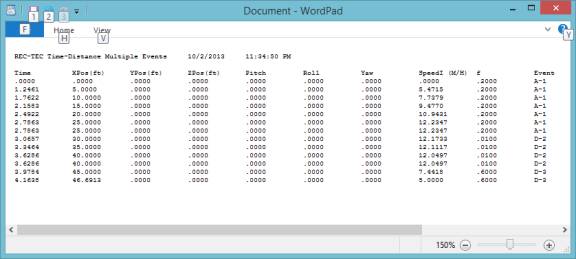

5: Time - Distance Multiple Events

Overview: This module computes the intermediate and

final speed, distance and time data for multiple (250) acceleration,

deceleration, or constant velocity events.

The module will also decode and assist in analyzing CDR data that

may be presented in unfamiliar configurations such as metric accelerations (meters/second/second)

in Toyota vehicles, or others similarly equipped by changing the primary input

to meters/second and changing acceleration to rate instead of factor. After saving the file (as a precaution)

changing the configuration or opening the file at a later date with a different

configuration, will convert it to any configuration desired. Graphics, Tables, and Time

and Distance breakdowns are available.

At the REC-TEC pull down menu, select Time - Distance >

Multiple Events and the Time

Distance Multiple Events screen

appears (Figure 61).

Figure 61

Required Inputs

The required

input data depends on the user-selected maneuver for each vehicle or

object. Single-Surface Acceleration and

Single-Surface Deceleration modules can be referenced for information on the

required input data for these maneuvers.

Constant Velocity will require the Initial Speed and either

a Distance or a Time as inputs.

Figure 61 (Event Control) shows a Re Do from Event Entry Box. Enter event number that requires a change. If a correction is required, it will be

necessary to go back to the event with the error and proceed from that point.

Example

1: A

vehicle accelerates from a stop (fa = .2) for 25 feet. It then coasts (f = .01) for 15 feet before

decelerating (f = .6) to a final speed of 5 miles per hour.

Note: As shown in Figure

61, the Time - Distance Multiple Events module operates in the same

direction as the Arrow of Time.

Enter the first event in time as the first event.

Figure 62

Figure 62 shows the entry data for the

first of three events.

Figure 63

Click Add Event to proceed to next

event. Figure 63 shows the data entry

for the second of the three events.

Output totals for the first two events appear in the upper right of the

screen.

Figure 64

Click Add Event to proceed to next

event. Figure 64 shows the data entry

for the third of the three events. Output

totals for the first three events appear in the upper right of the screen.

Figure 65

Figure 65 shows the table created using

the Events (1-3) button.

Figure 66 shows a table created by using a

time interval of 0.5 seconds.

Figure 66

Figure 67 shows a table created by using a

distance interval of 5 feet.

Figure 67

If Graphics is selected from the

input screen, the graphics appear with the data incorporated into the same

screen (Figure 68). If the [Esc]ape

key is pressed with the graphics on the data screen, the Graphics will go to

full screen as shown in Figure 69.

Figure 68

Use the [Esc]ape key to display the

Graphics curves in full screen mode.

Figure 69

Event Control will dictate the data displayed in the Events,

Time, Distance, and Graphics buttons, as the Event

number can be set controlling what is displayed.

The TDME button will create an

output file matching the last table run in either Time or Distance.

Figure 70

What is the total time for this

example? What is the total distance for

this example?

Example

2: A

vehicle goes through the following maneuvers:

1.

Acceleration factor = .2 Initial

speed = 30 M/H Final speed = 60 M/H

2.

Constant speed Distance

= 264 ft

3.

Acceleration factor = .2 Initial

speed = 60 M/H Final Speed = 75 M/H

4.

Constant speed Distance

= 300 ft

5.

Deceleration factor = .3 Initial

speed = 75 M/H Final Speed = 60 M/H

6.

Deceleration factor = .6 Initial

speed = 60 M/H Final Speed = 45 M/H

7.

Constant speed Time

= 5 seconds

8.

Deceleration factor = .6 Initial

speed = 45 M/H Final Speed = 0 M/H

9.

Stopped for 30 seconds

10.

Acceleration factor = .2 Initial

speed = 0 M/H Final Speed =

45 M/H

11.

Constant speed Time

= 5 seconds

12.

Acceleration factor = .3 Initial

speed = 45 M/H Final Speed = 60 M/H

13.

Constant speed Distance

= 400 ft

14.

Deceleration factor = .75 Initial

speed = 60 M/H Final Speed = 0 M/H

Note:

All braking is at 100%.

Figure 71

What is the total distance?

What is the total time?

What is the Average Speed for the

sequence?

What is the total distance at the end of

Event 12?

What is the total time at the end of Event

12?

What is the Average Speed for the sequence

at the end of Event 12?

Figure

72

The Time and

Distance curves for all 14 events are shown in Figure 73.

Figure

73

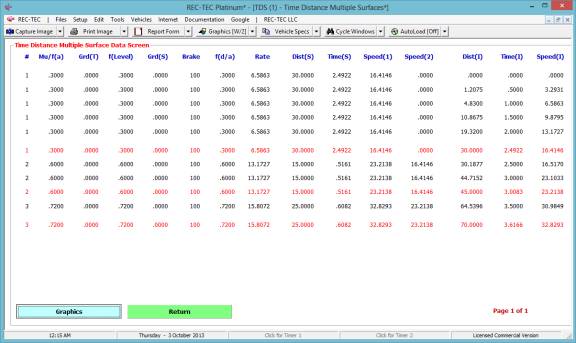

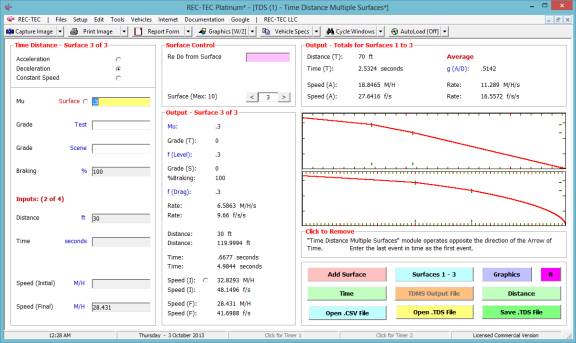

Module

6: Time - Distance Multiple Surfaces

Overview: This module computes the intermediate speed,

final speed, distance and time data over multiple surfaces in an acceleration,

deceleration or at constant velocity.

At the REC-TEC pull down menu, select Time - Distance >

Multiple Surfaces and the

Time Distance Multiple Surfaces screen appears (Figure 74).

Figure 74

Required Inputs

The required

input data depends on the user-selected maneuver for each vehicle or

object. Single-Surface Acceleration and

Single-Surface Deceleration modules can be referenced for information on the

required input data for these maneuvers.

Constant Velocity will require the Initial Speed and

either a Distance or a Time as inputs.

Example

1: A

vehicle decelerates from an unknown speed (f = .72) for 25 feet. It then decelerates over a second surface (f

= .6) for 15 feet before decelerating 30 feet (f = .3) to a stop. All Braking is 100%. What is the time and distance?

Note: As shown in Figure

74, the Time - Distance Multiple Surfaces module operates opposite the

direction of the Arrow of Time.

Enter the last event in time as the first event.

In Figure 75,

the last event (deceleration to a stop) is entered as the first event. Click Graphics to show them as seen in

Figure 75.

Figure 75

Click Add Surface to proceed to

next event. In Figure 76, the next event (event #2) is entered as the second

event.

Figure

76

Click Add Surface to proceed to

next event. In Figure 77, the first event (initial deceleration) is entered as the

last event.

Figure

77

Note

the Radio Button Next to the Initial Speed (Primary) See Page 11 for

details.

Press [Esc]ape to show (or clear) the full screen graphics of all

three events as displayed in Figure 78.

Figure

78

Press Surfaces

1-3 to show the data for all three events (Figure 79).

Figure

79

Figure 80 is the Time interval (0.5 seconds) breakdown of all

three maneuvers. This table also shows

the associated data at the change of events.

Figure

80

Figure 81 is the Distance interval (10

feet) breakdown of all three maneuvers.

This table also shows the associated data at the change of events.

Figure

81

Press TDMS

Output File to create the file (TDMSO.out) as shown in Figure 82.

Figure 82

Figure 83 (Surface Control) shows a Re

Do from Surface #1. If a correction is

required, it will be necessary to go back to the event with the error and

proceed from that point.

Figure 84 shows the effects of entering the

events in reverse order. While the

initial speed and total distance are the same, the times, including the total

time are not.

Figure 83

Please compare the data in Figure 77 with the data (and

graphics) in Figure 84.

Figure 84

Module

7: Time - Distance Time - Distance

(Acc~Dec)

Overview: This module computes detailed information on

the Speed, Distance and Time of an Acceleration-Transition-Deceleration event.

At the REC-TEC pull down menu, select Time - Distance > Time - Distance (Acc~Dec) and the Time - Distance (Acc~Dec) screen

appears (Figure 85).

Figure 85

Required Inputs

·

Speed

(Initial) Speed at start

of maneuver

·

fa (Acc) Acceleration factor (Zero if no acceleration)

·

Time (trn)

Transition time

·

f (Trn) Deceleration factor during Transition

(rolling resistance?)

·

f (Dec) Deceleration factor (Zero if no acceleration)

·

Speed

(Final) Speed at end of

maneuver

·

Distance (T)

Total Distance of maneuver

Example

1:

- Initial

Speed = 0

- f(acc)

= .2

- Time

= 1.5

- f(trn)

= .01

- f(dec)

= .7

- Final

Speed = 5 M/H

- Distance

= 125

Figure

86

The Iteration/FDA

button brings up the following menu.

Figure 87

Figure 88

The data in Figure 88 will automatically

be saved as Lastfile.ATD when the

program is exited. This data may

automatically be loaded if the AutoLoad

is On. It may be manually reloaded using the Open.ATD button. Using this

option, the top bar of the program screen will show the name of the loaded file

(Figure 89).

Figure

89

Figure 90 displays the Iteration table for the parameters shown in

Figure 88.

Figure

90

Figure 91 displays the Finite Difference Analysis for the

parameters shown in Figure 88.

Figure

91

Example

2:

- Initial

Speed = 30

- f(acc)

= 0

- Time

= 0

- f(trn)

= 0

- f(dec)

= .7

- Final

Speed = 0

- Distance

= 125

As shown in this example, this module does

not require much in the way of information to generate a solution. This module was primarily designed to assist

in the analysis of intersectional collisions involving vehicles and

pedestrians. It can be adapted to various situations.

Figure

92

Module

8: Time - Distance Time - Distance

Omni

Overview: This module computes

Acceleration/Deceleration factors and rates, Time, Distance, and/or Speed as

appropriate based on supplied information. It will create a table of

user-developed research data (pedestrian/vehicle study) for speed, time,

distance and/or acceleration/deceleration rates, which automatically integrates

into the Statistical Range (Monte Carlo) module in REC-TEC allowing

additional analysis (mean, range, variance, upper and lower bounds).

This very

powerful module does all of the basic computations of the Acceleration/Deceleration

Factor, Acceleration Single Surface and Deceleration Single

Surface modules of the program in a single module. It now provides for Graphics,

Iteration and Finite Difference Analysis. It does not allow for Lateral Distance (Swerve

/ Lane Change) computations, Grade, or Braking adjustments.

At the REC-TEC pull down menu, select Time - Distance > Time - Distance Omni and the Time - Distance Omni screen

appears (Figure 93).

Figure 93

Required Inputs

The required

input data depends on the user-selected maneuver. An Acceleration/Deceleration factor is not required. Single-Surface Acceleration and

Single-Surface Deceleration modules can be referenced for information on the

required input data for these maneuvers.

Constant Velocity will require the Initial Speed and

either a Distance or a Time as inputs.

Example 1:

A vehicle decelerates

for 100 feet to a final speed of zero (0).

1.

What is the

initial speed and time if the deceleration factor is .65?

2.

What is the

deceleration factor and initial speed if the time is 3 seconds?

3.

What is the

deceleration factor and time if the initial speed is 45 M/H?

Time - Distance Omni easily answers all three questions in the

same module.

Figure 94

The answer to question #1 is 44.1131 M/H and

3.0912 seconds (Figure 94).

Figure 95

The answer to question #2 is 0.6901 (f) and

the initial speed is 45.4545 M/H (Figure 95).

Figure 96

The answer to question #3 is 0.6763 (f) and

the time is 3.0303 seconds (Figure 96).

Time - Distance Omni also handles accelerations.

Example 2:

A vehicle accelerates

for 100 feet from an initial speed of zero (0).

4.

What is the

final speed and time if the acceleration factor is .2?

5.

What is the

acceleration factor and initial speed if the time is 5.5 seconds?

6.

What is the

acceleration factor and time if the final speed is 25 M/H?

Time - Distance Omni easily answers all three questions in the

same module.

Figure 97

The answer to question #1 is 24.4695 M/H and

5.5727 seconds (Figure 97).

Figure 98

The answer to question #2 is 0.2053 (fa) and

the initial speed is 24.7933 M/H (Figure 98).

Figure 99

The answer to question #3 is 0.2087 (f) and

the time is 5.4545 seconds (Figure 99).

Change the Distance to 65 and show the

Formula.

Figure 99B

Select Iteration by Factor and range from

.2211 to .4211 by .05.

Figure 99C

Results are shown in Figure 99D

Figure 99D

Using the setup in Figure 99C, do a Finite

Difference Analysis for Factor.

Figure 99E

Show the Graphics curves for the Problem

shown in Figure 99.

Figure 99F

Decelerate from 60 M/H for 100 using a

deceleration factor of .6 showing the Formulae and Results.

Figure 99G

Time - Distance Omni can also be used to time vehicles over a

known distance to calculate speeds.

This works with vehicles accelerating from a traffic control device,

tollbooth, or a truck weight station.

It can be used to time pedestrians crossing streets or other scenarios.

Example 3: Create a table of vehicles accelerating from a stop sign and clearing a point outside of the intersection (65 feet).

Note: The following screen captures have not been updated as the modifications shown above do not change these screens.

· Timer button Initiates the Timer mode but does not start the Timer.

· Start Timer button Starts the Timer (Enter will also start the Timer in Timer mode).

· Stop Timer button Stops the Timer (Enter will also stop the Timer in Timer mode).

·

Add to Data Table button Transfers the data from

the current run to the Data Table.

· Data Table Averages Displays the averages of the Entries in the Data Table.

· View Data Table Shows Data Table and allows selection of entries for further processing in the Statistical Range (Monte Carlo) module.

In the following example, 10 timing runs are simulated and entered into the data table.

In this Acceleration Example a vehicle is timed over 65 feet from a stop. Click on Timer. Click on Start Timer (or use Enter) to Start the Timer. Click on Stop Timer (or use Enter again) to Stop the Timer and display the results for this run.

If the Run was good, then Click Add to Data Table. If for some reason the Run went bad, simply ignore it and Time the next Vehicle.

The data table is averaged as the numbers are entered. After the runs are completed, the data table is displayed. The Speed (M/H) is selected for further analysis and written as a file, which is then opened in the Statistical Range (Monte Carlo) module.

The first run is displayed in Figure 100.

Figure 100

The first run has been transferred into

the data table and the Data Table Averages are shown in the upper right frame.

Figure 101

Figure 102 shows the averages for all 10 runs.

Figure 102

Figure 103 displays the Data Table with all of

the arrays. The Speed2 (M/H) column is

tagged for transfer into the Statistical Range (Monte Carlo) module for further

analysis.

Figure 103

Figure 104 displays the Statistical

Range (Monte Carlo) screen showing the graphics for a 100,000-point Monte

Carlo analysis for Final Speed.

Figure 104

Figure 105 shows the graphical display of the various

curves in the Statistical Range (Monte Carlo) module.

The circles are the points from the data table that were transferred in

order to make the analysis.

Figure 105

Figure 106 is the comma-delimited file that was created

from the Data Table (Figure 103).

Figure 106

Figure 107

Figure 107 is an example of how Time -

Distance Omni can be used to time pedestrians (or any moving object) to

compute the average speed involved.

This data can be transferred into an endless array data table for

further analysis in the Statistical

Range (Monte Carlo) module.

The Time - Distance Omni is a

real workhorse in analyzing many time-distance problems. It has the versatility and power to become

one of your most popular tools.

Module

9: Collision Avoidance Braking

Maneuvers

Overview: This module computes speed, time and

distance required to either stop before striking target vehicle, or decelerate

enough to allow crossing target vehicle to escape.

At the REC-TEC pull down menu, select Collision Avoidance > Braking

Maneuvers and the Collision Avoidance Braking Maneuvers screen appears (Figure 108).

Figure 108

Required Inputs

·

Mu

(Deceleration) - required

·

Grade (Test)

not required (default

is zero)

·

Grade

(Scene) not required (default

is zero)

·

Braking (%)

required

·

Speed (Veh

1) Initial Speed of

Vehicle 1

·

Impact

Distance Distance from End

of Reaction Time to Point of Impact

·

Reaction

Time Actual or Imputed

·

Speed (Veh

2) Speed of Vehicle 2

·

Clear

Distance Distance Vehicle

2 must travel to avoid contact

Example 1:

A vehicle decelerates

from 60 M/H on a surface with a .6 coefficient of friction. There is no grade and the vehicle braking is

100 percent. After a

Perception-Reaction time of two seconds, it travels 100 feet striking vehicle

#2. Vehicle #2 is traveling at 30

M/H. If vehicle #2 had traveled 10 more

feet, it would have cleared the path of Vehicle #1.

1.

What is the

maximum speed of Vehicle 1 for it to stop before contacting Vehicle #2?

2.

What is the

maximum speed of Vehicle 1 for it to pass safely behind Vehicle #2?

3.

What is the

speed of Vehicle 1 as it passes behind Vehicle #2 in question #2?

Figure 109

Figure 110

As can be seen in Figure 109, the only

option offered by this module is showing the Diagram (Figure 110). The data generated by this module is a bit

overwhelming at first glance.

The F1 (Help) file will help

decipher the output data (Figure 109) and placing the cursor on a particular

piece of data will display a ToolTip describing the data.

While there is a huge amount of

information on Figure 108, the diagram (Figure 109) helps to filter the data making

the problem easier to understand.

Unfortunately, a closer look at Figure 110 may raise more questions than

it answers. For example, the entered

distance between the PRT and impact is 100 feet (Figure 108), yet in Figure 109

the distance is shown as 132.7561 feet for the STOP scenario and 107.6771 feet

for the CLEAR scenario.

In the data entry, the distance is 100

feet. This 100-foot distance is the

deceleration distance from an initial speed of 60 M/H, resulting in a

collision. Given the same total

distance for the reaction time and the deceleration, the module computes that

if the initial speed was 48.8331 M/H, then Vehicle #1 could come to a complete

stop just short of striking Vehicle #2.

Using this same distance and an initial speed of 57.3827 M/H, Vehicle 1

could have decelerated and passed safely behind Vehicle #2 without a collision.

Understanding the principles put forth in

the above paragraph, the data shown on Figure 109 should make more sense. All three maneuvers, the collision, the stop

and the clear must all use the same total distance. The times will vary with the different speeds, but the total

distance available is the same in all three.

The data entered into the problem must

describe a collision. If the distance

entered is over 200.414 feet, there never would be a collision as Vehicle 1

would be able to stop before striking Vehicle 2 and there would be no reason to

use this or any other module in the program.

Once that collision is described, the module will compute the maximum

possible speeds both to STOP, and to CLEAR.

Included in the data shown on Figure 109

is the impact speed based on both time and distance for the input speed of 60

M/H. The result is a collision speed of

43.4702 M/H. In the Brake to Clear

frame on Figure 108, the Speed (Clear) data is the speed that Vehicle 1 would

have at the time it passed behind Vehicle 2.

Example

2: In this example, use the same data for Vehicle

1. For Vehicle 2 change the speed and

the clear distance both to zero (0).

Figure

111

With these changes in place, there can be

no solution for questions 2 and 3. The

diagram (Figure 112) shows the impossibility of the solution.

Figure

112

Module

10: Collision Avoidance Collision

Analysis

Overview: This module computes the speeds, times and

distances during which the vehicles are exposed contact and during which

contact will actually occur.

At the REC-TEC pull down menu, select Collision Avoidance >

Collision Analysis and the Collision Avoidance Collision Analysis screen appears (Figure 113).

Figure 113

Data Entry: Entries for either Vehicle can consist of Acceleration, Deceleration

or Constant Speed and will contain two or more of the following data

entry blocks within the two leftmost frames:

·

g Acc/Dec (Acceleration/Deceleration required)

·

Speed

(Initial)

·

Speed

(Final)

·

Reaction

Time

·

Distance Distance from front of vehicle to center of

vehicle paths at impact

·

Length (LOV)

·

Width (WOV)

·

Intercept

Angle Angle between

vehicles

Example 1: At time

zero, Vehicle 1 starts 150 feet from point (0,0). After a 0.75 second reaction time, it begins decelerating at 0.7

g from an initial speed of 60 M/H to a final speed of 30 M/H. Vehicle 1 is 16 feet long and 5 feet wide. Vehicle 2 starts 15 feet from point

(0,0). At time zero, it begins to

immediately accelerate at 0.25 g from a stop to a final speed of 10 M/H. Vehicle 2 is 18 feet long and 6 feet

wide. The intercept angle of the paths

of the units is 90 degrees. The paths

will cross at point (0,0)

What is the start time and end time during

which the vehicles are trying to occupy the same space?

What is the start distance and end

distance during which the vehicles are trying to occupy the same space?

What is the start speed and end speed

during which the vehicles are trying to occupy the same space?

Figure

114

Figure 115

Example 2: With a 45

degree intercept angle, how would the answers differ from those in Example 1.

Figure 116

Example 3: With a 135

degree intercept angle, run the problem with a stop time of 1.56 seconds and

show the results.

Figure 117

Module

11: Collision Avoidance Following

Maneuvers

Overview: This module computes the speed, time and

distance at which a maximum rate deceleration or an evasive maneuver must begin

in order to match the speed of the (accelerating, decelerating or

constant-velocity) lead vehicle, thus preventing a collision.

At the REC-TEC pull down menu, select Collision Avoidance >

Following Maneuvers and the Collision Avoidance Following Maneuvers screen appears (Figure 118).

Figure 118

Required Inputs:

·

V1 Speed (I) Following (Bullet) Vehicle at Start of

Maneuver

·

V2 Speed (I) Leading (Target) Vehicle at Start of

Maneuver

·

RSAVT (Rads/Sec) Relative Subtended Angular Velocity

Threshold in Radians per Second

·

V2 Dimension Height or Width Cue for Subtended Angular

Rate Change Computation (Height/Width of Trailer or Distance between tail

lights

·

Min Lat. Dist. Minimum Lateral Distance (Turn / Lane

Change)

·

Reaction Time Time before V1 reacts to V2 maneuvers

·

Safe Distance Separation Distance Between Vehicles at

Speed match

·

Acceleration (+/-) (V1) Acceleration Factor if V1

Accelerating (+/-) prior to entering Max rate Deceleration

·

Lateral Accel. (V1) Lateral (Y-Axis) Acceleration Factor

- Required

·

Acceleration (V2) Acceleration Factor (X-Axis) if V2

Accelerating (+/-)

·

Maximum Decel. (g) Maximum Available Deceleration (g)

Example 1:

Vehicle 1 (bullet) is

traveling at 70 M/H. Vehicle 2 (target)

is traveling in the same direction at 10 M/H.

V2 width is 7 feet (used with RSAVT).

The minimum lateral distance to avoid collision is also 7 feet. Vehicle 1 is capable of accelerating laterally

at 0.2 g. Vehicle 2 is accelerating at

0.15 g. The maximum deceleration factor

for Vehicle 1 is 0.7g. Reaction time

for Vehicle 1 is 2 seconds and distance required between vehicles at speed

match is 25 feet. RSAVT is 0.006.

On Figure 119 there are computations that

would be difficult to solve for without this module as you are effectively

trying to land a satellite on a comet that could be accelerating

(positive/negative).

Figure 119

Primary Output:

1

V1

Dist Contact (Spd Match): V1 - Distance

to Contact (Spd Match) from Time Zero (0)

2

V2

Dist Contact (Spd Match): V2 -

Distance to Contact (Spd Match) from Time Zero (0)

3

V2 Acc (+/-) Time: Includes time V2 is Accelerating (+/-) before V1 begins

Decelerating

4

V1

Dss: Distance to Decelerate from

Initial Speed at Maximum f

5

V1

Tss: Time to Decelerate from Initial

Speed at Maximum f

6

V1

Maximum f: Maximum Deceleration Factor

(g)

7

V1 Max Dec

Dist.: Distance Required to match V2

Speed - Maximum Deceleration (g)

8

V1 Max Dec

Time: Time Required to match V2 Speed

- Maximum Deceleration (g)

9

V1 @ V1 MaxD: V1 Speed (Primary)

at V1 Maximum Deceleration Start

10

V2 @ V1 MaxD: V2 Speed (Primary)

at V1 Maximum Deceleration Start

11

Event Max Dist.: Maximum Distance

from Time Zero (0)

12 Event

Max Time: Maximum Time from Time Zero (0)

Animation The display (Figure 115) shows the

acceleration curves for both vehicles in the upper block and the Turn (upper

middle block) and Lane Change (lower middle block). Time (top scale) and

Distance (bottom scale) is shown for all three curves. Animation may be stopped

and resumed using the mouse or the spacebar. [Esc] to Exit

Tables Tables show either, the f required to clear (Match V2 Speed) and

Closing Speed at Maximum Available Deceleration from Time frame, or the

Subtended Angle (Radians) and Rate of Change of the Subtended Angel in

Radians/second. Both tables display Time in user selectable increment to Point

of Contact. Table data includes instantaneous speeds for V1, V2, Closing Speed,

required distance for Turn and Lane Change, Separation Distance between

Vehicles and Time to Impact and Distance traveled by V1 and V2.

Figure 120

Figure 121

Figure 121 includes the menu choice (f/Clear

or Visual) and the time interval for the Table. Figure 122 displays the f/Clear table and Figure 123 displays the

Visual (RSAVT) table.

Figure 122

Figure 123

On both tables (Figures 122 fClear

and 123 Visual), the value in the 10th column changes color

from green to red. On Figure 122, the

column labeled Vc@f(.7) shows the collision speed at the maximum deceleration

rate. A negative speed value would mean

that the vehicle (V1) could be backing

up at that speed if the deceleration (acceleration) values were maintained.

Figure

123A

Figures 123A and 123B show V1 data

automatically transferred to Time Distance Multiple Events for further

analysis and as a cross check on both the math and the graphics.

Figure

123B

Figure 123C

Figure 123C shows V2 data automatically

transferred to Time Distance Omni for further analysis and as a cross

check on the math with graphics diagrams available.

Module

12: Collision Avoidance Passing

Maneuvers

Overview: This module computes the Time and Distance

required to complete a passing maneuver.

Note:

REC-TEC uses a

Circle as the model in computing Turn information. All of the other popular Turn formulae use a

Parabola as their model. The result

is that the term lateral has two very different connotations in discussing

turning accelerations. In REC-TEC

(Circular) the lateral acceleration is always perpendicular to the

instantaneous direction of the vehicle except in this module where the user is

given a choice. In the other formulae

(Parabolic) the term lateral references the initial direction of travel of

the vehicle and the acceleration is always perpendicular to that initial

direction.

At the REC-TEC pull down menu, select Collision Avoidance > Passing

Maneuvers and the Collision Avoidance Passing Maneuvers screen appears (Figure 124).

Figure 124

Required Inputs:

·

Pass ( ) L (

) R V1 past to Left

or Right of V2 (used for Diagram and Animation output files)

·

Circle (

) Parabola ( ) Selects Circular or Parabolic

formulae for lane changes (Turns)

·

V1 Speed (I)

Speed at start of Maneuver

·

V2 Speed (I)

Speed at start of Maneuver

·

V1 Length

·

V2 Length

·

Lane Centers

(D) Distance between Lane

centers

·

Separation

(I) Initial Separation

Distance (X-Axis) between Vehicles after first Lateral acceleration (lane

change)

·

Accel (V1)

Initial Initial

Acceleration factor (X-Axis) if V1 accelerating

·

Lat. Accel

(V1-1) Lateral (Y-Axis)

Acceleration factor (required)

·

Pass Accel

(V1) Passing Phase

Acceleration factor (X-Axis) Required if V1 accelerating

·

Pass Accel

(V2) Passing Phase

Acceleration factor (X-Axis) Required if V2 accelerating

·

Lat. Accel

(V1-2) Return Lateral

(Y-Axis) Acceleration factor (required)

·

Accel (v1)

Final Final Acceleration

factor (X-Axis) if V1 accelerating

·

Separation

(F) Final Separation

Distance (X-Axis) between Vehicles before second Lateral acceleration (lane

change)

The Pass is broken down into three separate

phases. Phase 1 is the initial

longitudinal acceleration phase and the first lateral acceleration phase. Phase 2 is the passing phase. Phase 3 is the final longitudinal

acceleration phase and the second lateral acceleration phase. (See Figure 126)

Example 1:

Vehicle 1 is 16 feet

long and Vehicle 2 is 17 feet long.

Vehicle 2 is traveling at 50 M/H.

Vehicle 1 is accelerating from 55 M/H at 0.05 g longitudinally while

accelerating laterally at 0.1 g in order to pass Vehicle 2, which is 40 feet

ahead. In the passing phase, Vehicle 1

will accelerate at 0.05 g and Vehicle 2 will accelerate at 0.025 g until

Vehicle 1 is 60 feet in front of Vehicle 2 before accelerating laterally at 0.1

g while decelerating longitudinally at 0.01 g.

Figure 125

Figure 126

Total Distance is 1447.3757 feet. Total Time is 15.6639 seconds. Vehicle 1 final Speed is 67.1088 M/H.

Example 2:

Remove

the acceleration for Vehicle 2 in Example 2 and compare the Distance, Time, and

final Speed from Example 1. (Figures

below show R for Pass and Circle for formulae selection)

Figure 127

Figure 128

Total Distance is 1351.9898 ft, Total Time is

14.6717 seconds, and Vehicle 1 final Speed is 66.0181 M/H using Circular formulae.

Figure 128B

If using Parabolic formulae the Total

Distance is 1342.7492 ft. Total Time

is 14.6697 seconds. Vehicle 1 final

Speed is 66.0174 M/H.

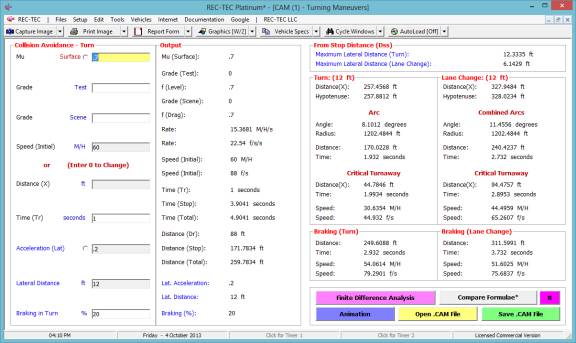

Module

13: Collision Avoidance Turning

Maneuvers

(Table of Contents)

(Table of Contents)

Overview: This module computes data on Turn and Lane

Change maneuvers, including braking during the turn, and compares different

common formulae used in accident reconstruction.

At the REC-TEC pull down menu, select Collision Avoidance > Turning

Maneuvers and the Collision Avoidance Turning Maneuvers screen appears (Figure 129).

Figure 129

Required Inputs:

·

Mu

(Deceleration): required

·

Grade

(Test): not required

(default is zero)

·

Grade

(Scene): not required

(default is zero)

·

Speed

(Initial): Speed of

vehicle - Computes Distances for Turn and Lane Change Maneuvers or (Enter

zero to change)

·

Distance

(X): Distance of Swerve

(X-Axis) - Computes Initial Speed for Maneuver and Lane Change Distance

data

·

Time (Tr):

Reaction Time

·

Acceleration

(Lat): Lateral

Acceleration factor

·

Lateral

Distance: Distance CG must

move in Lateral Direction.

·

Braking in

Turn: Optional Percent

of braking in Turn (must be less than 100)

Example 1:

A vehicle enters a

turn at 60 M/H. It will accelerate

laterally at 0.2 g. The Lateral

distance is 12 feet. The road has a Mu

(drag factor) of 0.7.

What is the distance traveled by the vehicle

for the turn?

What is the time for this event?

What is the distance traveled by the vehicle

for the lane change?

What is the time for this event?

What is the distance and time required for

the vehicle to come to a full stop at a 0.7 g deceleration?

Figure 130

Turn: Time = 1.932 seconds | Distance Traveled = 170.0228 feet

| Distance on X-axis = 169.4568 feet

Lane Cng:

Time = 2.732 seconds | Distance Traveled = 240.4237 feet | Distance on

X-axis = 239.9484 feet

Full Stop: Time = 3.9041

| Distance Traveled = 171.7834 feet

Figure 131

Figure 132 shows a comparison of the

popular formulae used in accident reconstruction. Notes explain the differences in the focus of the formulae and

the parameters inherent in their output.

Figure 132

Figure 133

Figure 133 displays the Finite Difference

Analysis Menu. The menu allows

selection of any of the formulae used in the Formulae Comparison Chart. It also allows for the selection of a Turn

or a Lane Change as the subject of the analysis. The results of a Turn are shown in Figure 134 and a Lane Change

in Figure 135.

Figure 134

Figure 135

Example 2: This

example will use the same basic information, but will add 20% braking during

the maneuver.

What is the distance traveled by the vehicle

for the turn?

What is the time for this event?

What is the distance traveled by the vehicle

for the lane change?

What is the time for this event?

Figure 136

Turn: Time = 1.932 seconds

| Distance Traveled = 161.6088 feet | Final Speed = 54.0614 M/H

Lane Cng:

Time = 2.732 seconds | Distance

Traveled = 233.5991 feet | Final Speed = 51.6025 M/H

Note:

Braking in Turn

This option opens up two additional frames in the solution panel. The formulae for this solution are not used

in Formulae Comparison, Animation, or in the Finite Difference Analysis.

Example 3: The times

with and without braking in the turn and in the lane change are the same.

- Prove

that the time for the Turn and Lane Change is correct if the Distance

computed is correct.

- Explain

why we know this is correct.

Answers

1A. 161.6088 / ((88 +

79.2901) / 2) = 1.932

1B. 223.5991 / ((88 +

75.6837) / 2) = 2.732

2. See Figures 136 and

137 after you

have tried to figure out the solution.

Figure 137

Allowing for a small difference

between acceleration perpendicular to the initial direction of travel and

acceleration perpendicular to the instantaneous direction of travel (REC-TEC), this is the same as the

answer in 1A.

Figure 138

Allowing for the small difference detailed above, this is the same

as the answer in 1B as there are two separate accelerations, one from zero to 6

feet and one (deceleration) from 6 feet to zero. (1.365 * 2 = 2.73)

Proof of Concept using

Circle versus Parabola as model for Turn formula

Overview:

REC-TEC uses a

Circle as the model in computing Turn information. All of the other popular Turn formulae use a

Parabola as their model. This Proof of